Introduction to Industry 4.0

- FutureFactor360

- Sep 30, 2021

- 3 min read

Over the course of manufacturing history, global enterprises have adopted various levers to lower cost, increase productivity, enhance quality & create product differentiation.

Each industrial revolution has enabled a significant jump in each of the above business metrics

How did we get here?

Brief overview of the industrial revolutions thus far

Industry 1.0: Introduced mechanized production capabilities that allowed economic mass production. The focus was on efficiency and scale

Industry 2.0: Led by the advent of machines that ran on electricity. Helped achieve greater production quality and resource utilization

Industry 3.0: Facilitated by advances in the electronics industry. It marked the large-scale adoption of technology and IT systems for the first time. The usage of advanced electronic and automated systems such as PLCs helped automate processes and achieved increased production speed, greater accuracy and lower operating costs

Industry 4.0: A combination of cyber-physical systems and IoT is helping create a virtual, transparent and real-time view of production. Leveraging advanced digital technologies today allows for full automation of manufacturing

What we mean by Industry 4.0

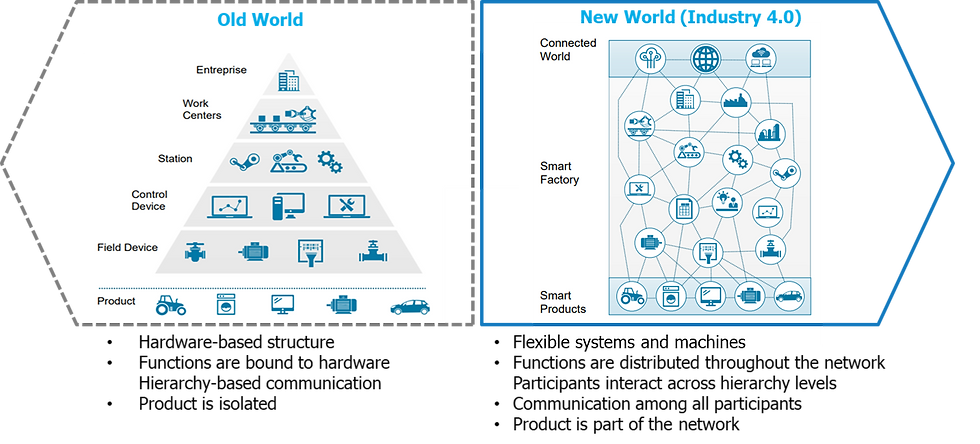

Industry 4.0 is a name given to the current trend of automation and data exchange in manufacturing technologies. It encompasses the digitalization of the horizontal and vertical value chain, innovation in products, processes, people practice and creation of new business models

What makes Industry 4.0 different

The fusion of emerging technologies and their interaction across the physical, digital and biological domains make Industry 4.0 fundamentally different from the previous revolutions – diffusing faster and more broadly across various industries and functions.

The disruptive technologies, driven by exponential rise in data volumes, computing power, connectivity and low costs of storage are giving companies the opportunity to adapt their business models to capture new value pools.

I4.0 comprises of below design principles

Evolutionary: The ability to constantly review and adopt pioneering technological innovations

Convergence: Merger of previously separated processes, systems, technologies, business units and solutions

Interoperability: The interconnectedness of devices and systems will require interoperability of the entire infrastructure to reduce integration complexities

Modularity: Modularity approach offers the advantage of transparency allowing much higher levels of decentralized action and decision making

Personalization: I4.0 paves the way for transitioning from mass customization to mass personalization production

Real-time: Availability of intelligence and data insights in real-time enable maximum transparency and better decision making

Virtualization: The merger of physical and digital worlds will give rise to connected system of systems (Cyber-Physical systems)

Servitization: Enables new business models that can be leveraged via connected products to create a more personalized experience for customers

Key growth drivers for Industry 4.0

The rapid global adoption is being driven by key factors such as:

Low cost of computation and storage

Advancements in sensor/ connectivity technology

Ease of integration between disparate systems (through APIs, Data Lakes)

Emergence of analytics and business-intelligence systems

New forms of human machine interfaces

Rise of emerging digital technologies

Reduced Production Costs

I4.0: Levers of Value Creation

Industry 4.0 brings many avenues to create business value, improve productivity and quality.

10-30% reduction in design and engineering costs

20-50% decrease in inventory holding costs

20-50% reduction in time-to-market

10-20% reduction in costs for quality

3-5% increase in overall productivity

45-55% increase of productivity through automation of knowledge work

30-50% reduction of total downtime

85%+ increase in forecasting accuracy

Source: McKinsey Industry 4.0 Global Expert Study

Outlook

Given the current trends and value creation potential, it is certain that Industry 4.0 is not just one of the trending buzzwords.

Industry 4.0 will lay the foundations to the future of global businesses as we imagine it today: by enabling a connected, smart, intelligent enterprise

Executives should take Industry 4.0 into consideration as they draft the company’s growth strategy. They must be quick to recognize business opportunities enabled by Industry 4.0 and also watch for peers adopting them.

It is important to acknowledge that Industry 4.0 is not just about making isolated investments through pilots but taking a more holistic approach to digital transformation of the organization across the pillars of people, products, processes and technology.

Comments